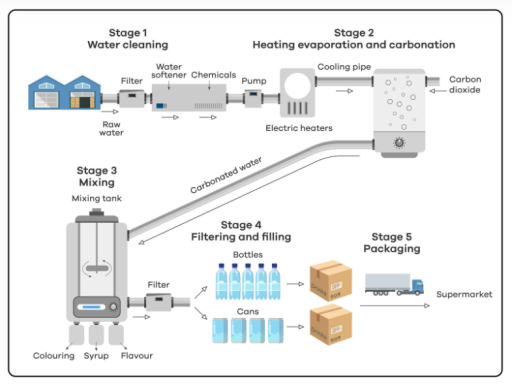

The diagram gives information about the process of making carbonated drinks.

The diagram illustrates the sequential stages in the manufacture of carbonated drinks, from the purification of raw water to the final distribution of the packaged product.

Overall, the process comprises five main stages: water purification, heating and carbonation, mixing, filtration and filling, and packaging. Each step is essential in transforming untreated water into a finished beverage ready for sale.

In Stage 1, raw water is passed through a filter to remove impurities, then softened and treated with chemicals to ensure it meets safety standards. The purified water is then pumped into Stage 2, where it is heated in an electric heater and subsequently cooled via a cooling pipe. Carbon dioxide is added to the cooled water in a carbonation chamber, producing the base carbonated water.

In Stage 3, the carbonated water enters a mixing tank, where colouring, syrup, and flavouring are added to create the desired taste and appearance. Stage 4 involves final filtration, after which the drink is filled into bottles or cans.

Finally, in Stage 5, the packaged beverages are boxed and transported to supermarkets for retail sale. The process is carefully controlled at each stage to ensure both quality and consistency.